Do you know any cutting tool that can cut through almost any material? WE GOT IT!

Laser Cutting

Trimming of highly deformable cloth, cutting of rigid metal sheets, or even processing of organic material is all possible with one and the same tool. Laser-based cutting system are all-pervasive and are applied in industries, such as textile, automotive, aerospace, shipbuilding but also in the medical area.

Laser Cutting is a thermal laser-based cutting process usually used for two- dimensional pieces e.g. metal sheets, wood panels, organic materials and three-dimensional bodies, such as tubes. The process of laser cutting utilizes optics of a high-capacity laser source pointed at a workpiece, which then melts, burns, vaporizes, or blows away with a jet of gas creating a cut kerf on the job. In contrast to conventional cutting methods laser cutting offers several advantages such as a fast cutting speed, a non-contact cutting process and the absence of additional tool wear, which results in reduced operation time, high accuracy and an increase in productivity.

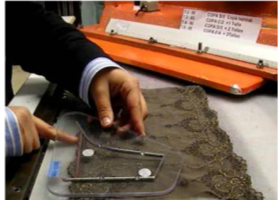

Especially in the manufacturing of highly deformable materials like fabrics, submillimeter accuracy in the localization of matching points, adapting the trajectory to smooth deformations, detecting abrupt wrinkles that would produce defective cuts are highly essential. Concerning the handling of the machinery, the system should be operable in a self-explanatory and intuitive manner, and without any sophisticated staff training on system programming or operation. Examples of challenging cutting tasks can be found in the following Laser-based Equipment Assessments (LEA):

CUDE - Direct diode laser system for cutting of mild and stainless steel

MOBILLAS - Mobile laser system for on site material processing

TWOMICRO - Two micron laser source for light weight materials and medical sector

ALPS - Vision based laser cutting of patterned fabrics

Fraunhofer Institute for Laser Technology ILT

Fraunhofer Institute for Laser Technology ILT